About us

Today, Electraplan is one of the largest manufacturers of mounting systems for photovoltaic panels in Hungary. Due to continuous investments the production capacity exceeds 800 MW/year, Electraplan processes more than 25,000 tons of steel annually.

In addition to production, a team of engineers not only plans and develops mounting systems but also designs turnkey PV parks, with current developments in Hungary in various phases totaling over 200 MW.

In Romania we aim to have a direct relationship with the end customer, visiting future construction sites to identify solutions together with the beneficiary. The results of the field surveys go back to the design table to optimize the offered solution, bringing added value to the client.

Because we offer solutions based on the specific needs of each project, each technical-commercial offer is unique. That's why we do not operate with price lists and cannot give you a separate offer on the components of the installation systems.

Sustainability

While we want to create value from harnessing a renewable energy source, we are aware that most natural resources are finite. That's why throughout the production cycle we work to minimize our impact on the environment.

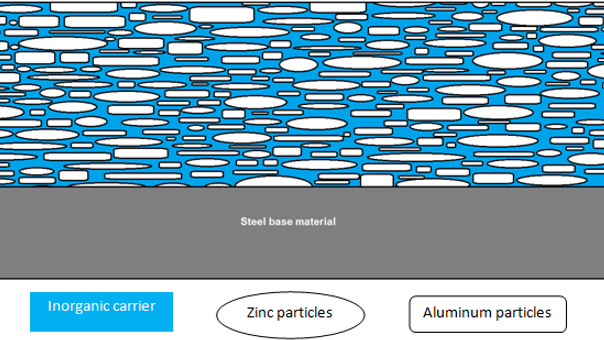

Our aim is to constantly improve. Producing quality and sustainable products, the possibility of recycling them completely, the use of innovative production technologies ( zinc flake coating ) are just some of the measures taken by our company in this direction. More than 50% of the energy we use is produced at our sites from renewable sources.

Factory/Technology

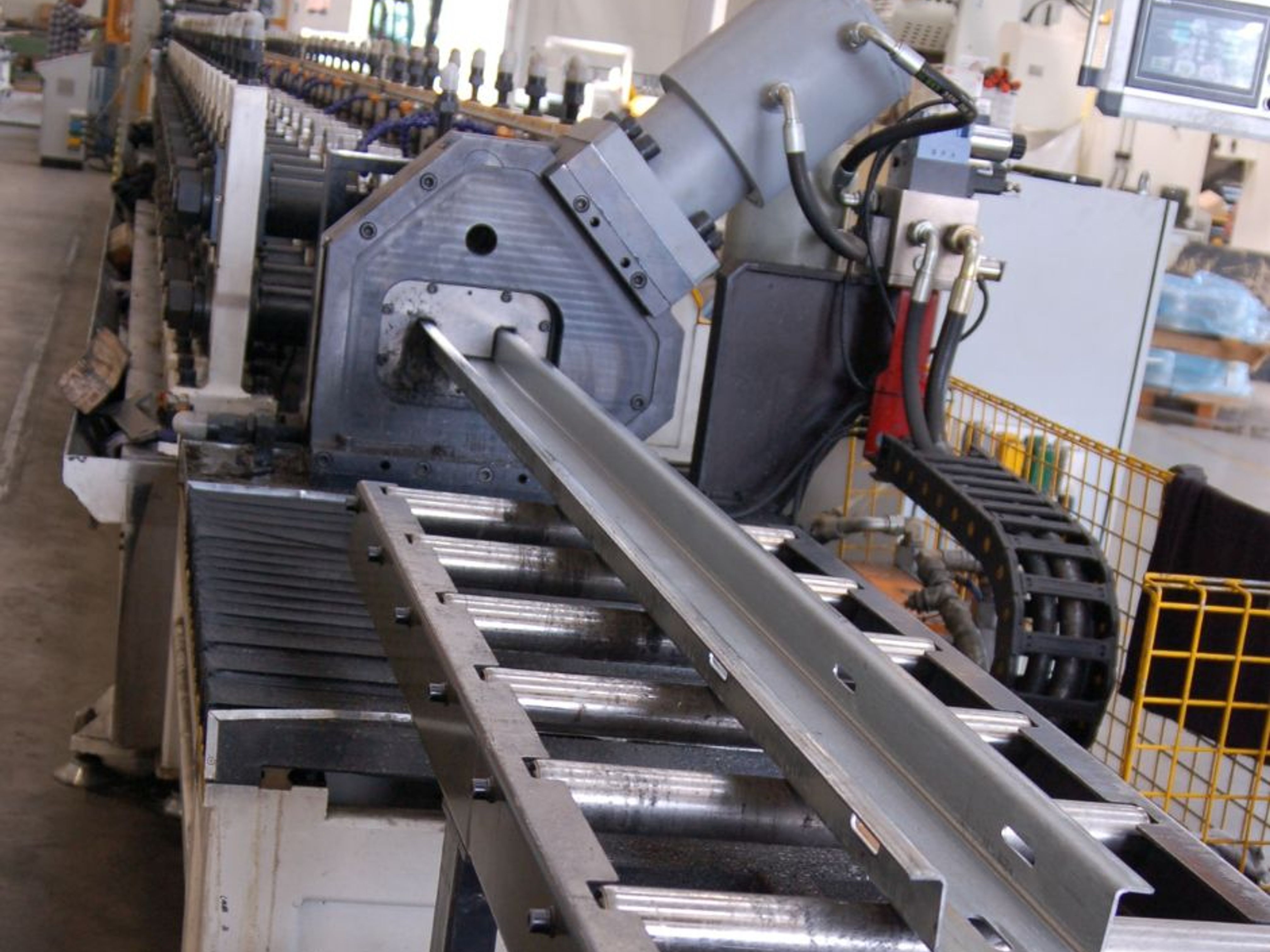

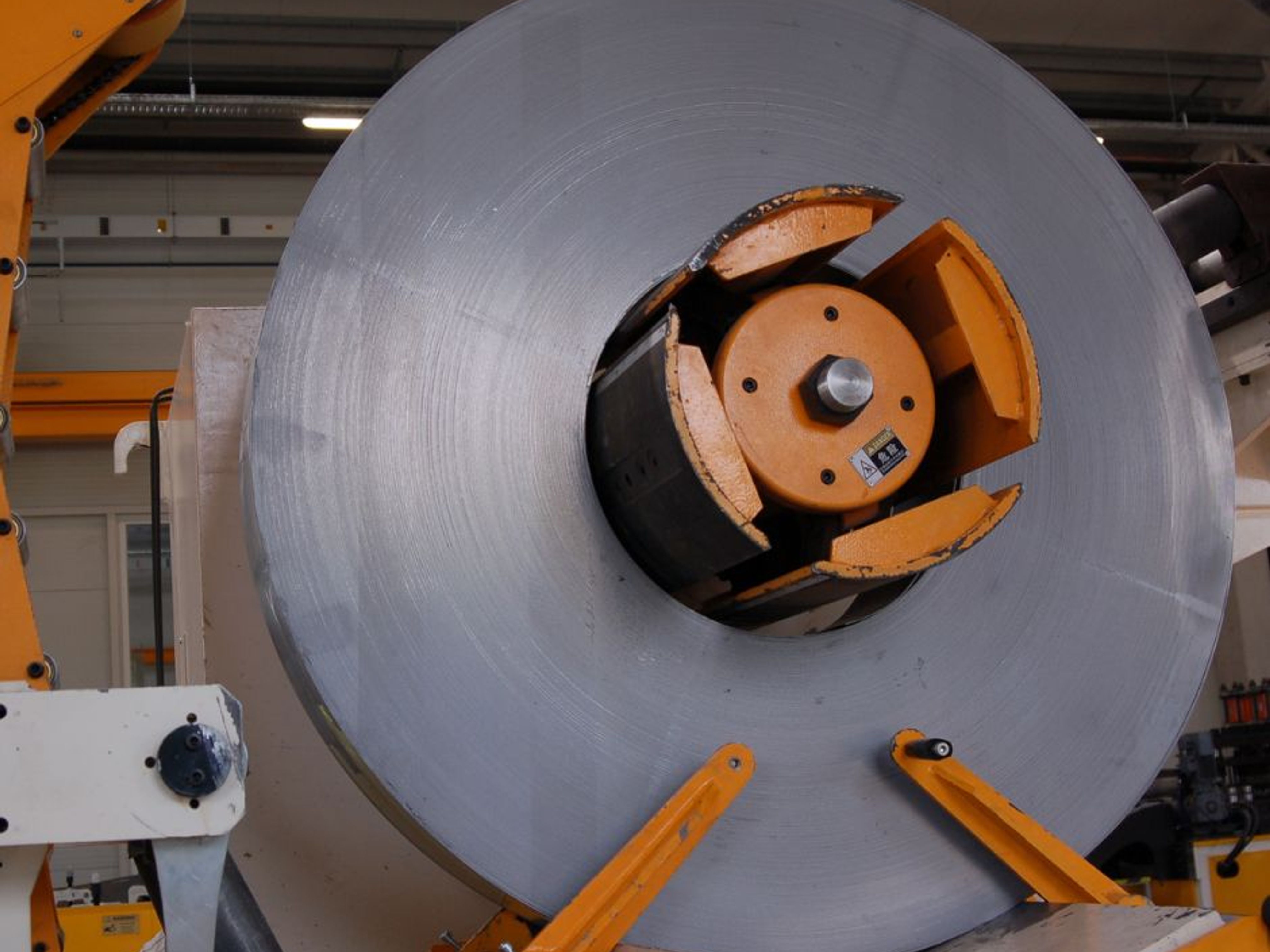

More than 100 full-time employees work at the central production facility in Vésztő. In case of large orders it is possible to introduce additional shifts to support our customers with shorter delivery times. Apart from Vésztő, production is also carried out in Nyirád and Óhíd (located in the south-western part of Hungary).

Electraplan is constantly investing in the development of production lines and new manufacturing technologies. The new hall built in 2022 is being equipped with a galvanizing unit using the so-called zinc flake coating technique according to EN ISO 10683:2014 and EN ISO 13858 (zinc flake coating). This technology offers very good corrosion resistance between 240-3000 h NSS (neutral salt spray hours) compared to electroplating and passivation (24-200 h NSS) or compared to the zinc immersion process (200 -2000 h NSS).

Corrosion protection

-

The steel sheet used for the profiles that make up the E-Solar photovoltaic panel support system is S235 or S350 brand steel (S stands for structural steel group, the figure reflecting the minimum yield strength in N/mm2). The sheet suppliers are renowned manufacturers ArcelorMittal and Wuppermann.

-

Corrosion protection is provided by a protective coating of Magnelis® zinc-aluminum-magnesium alloy or similar, depending on the manufacturer of the raw materials used for each project.

-

Steel plate is processed only by ‚‚cold’’ processes that prevent surface melting of the Zn-Al-Mg alloy. High-tonnage presses are used for punching, roller lines for profiling and guillotines for cutting resulting in clean smooth surfaces.

-

Since zinc provides sacrificial protection, these small surfaces will not affect the corrosion resistance of the coating.

-

Sacrificial protection: due to the electronegative nature of zinc (E = -0.76 V) compared to iron (E = -0.44 V), in the Zn-Fe couple zinc becomes anode and corrodes (sacrifices), while the substrate steel does not corrode because it becomes cathode (is cathodically protected). After the zinc layer is destroyed by corrosion, the corrosion products (zinc oxides - so-called 'white rust') remain on the steel, isolating it from the environment and thus providing further corrosion protection.

-

The occurrence of ‚‚white rust’’, i.e. zinc oxide staining or so-called ‚‚galvanic chalking’’, i.e. the appearance of zinc oxide grains does not affect the service life of the steel structure. Galvanic flour deposits are granular deposits of zinc slag in contact with the environment. White rust on the surface is the end product of moisture condensation on the surface of galvanized steel. The quality and service life of the product are not affected by the formations mentioned above, which are therefore not considered to be defective.

Careers

Because we are in a development process, we are looking for new colleagues. If you are passionate about renewable energy, motivated and have a technical background, we welcome you to join our team. Please send your CV together with a cover letter to office@eplansolar.ro with HR in the subject line of the email.